- Portfolio

- Product

Portfolio

BackSpark® Top II NDtech

The world's most advanced sparkling wine stopper

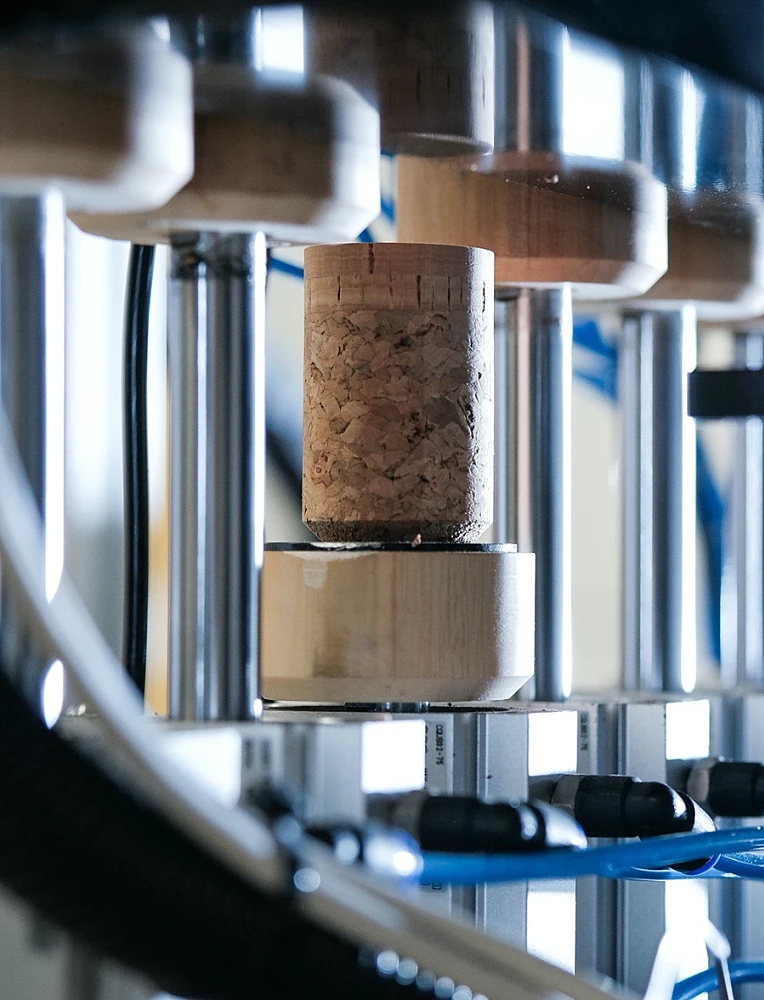

NDtech is the industry's most advanced screening technology

The Spark Top II NDtech® stopper is subject to exclusive ultra-fast gas chromatography technology, which analyses each cork stopper individually, automatically separating out stoppers with a releasable TCA content of more than 0.5 ng/L, guaranteeing maximum sensory neutrality.

Produced from 100% recyclable natural cork, Spark Top II NDtech® stoppers also benefit from the ROSA, FBT and CorkNova processes to offer the desired sensory safety and fulfil the highest quality standards.

100% of the stoppers with natural cork discs are analysed by X-ray, guaranteeing their homogeneity and physical-mechanical resistance.

Spark Top II NDtech® offers the highest quality, providing a unique and consistent experience in every bottle.

Cork Properties

- 48 x 31 mm

- 48 x 30.5 mm

- 48 x 29.5 mm

- Amorim can calculate the required cork diameter by studying the internal profile of the bottleneck, the characteristics of the wine and the corking conditions.

- Order your cork stoppers for immediate or short-term use. Ideally, these cork stoppers should be used within four months of the date of manufacture if the storage conditions are respected.

- Store the cork stoppers in their original packages, in a well-ventilated room with controlled temperature between 15°C and 25°C and 50% to 70% humidity.

- Do not leave boxes and/or bags open with surplus cork stoppers.

- Ensure any dust its removed before corking.

- Ensure the cork is compressed smoothly, to a diameter 1.5 to 2 mm smaller than the diameter of the bore of the bottle.

- Ensure insertion of the cork is as quick as possible.

- For standard bottlenecks, the cork should be inserted at 24 mm ± 2 mm from the top of the neck with the wire wood applied.

- Minimise moisture on the inside of the bottleneck.

- Don’t leave the cork stoppers in the feeder as to avoid dust.

- Always use stoppers with a surface treatment suitable for the type of beverage, bottling process and selected bottle.

- Ensure that all dust is removed using suitable placed aspiration – particularly before inserting the cork stopper.

- Maintain the corker jaws free of nicks and signs of wear.

- Ensure proper alignment of plunger and location ring.

- Ensure corking machine operates smoothly, especially during compression.

- Clean all cork-handling surfaces regularly with chlorine-free products.

- Ensure the equipment is suited to the cork and bottle used.

- After bottling, the bottles should be kept in an upright position.

- Ideal bottle storage conditions are 12–18°C at 50–70% humidity.

- Keep the wine cellar free of insects.

- Bottles should be stored and transported in an upright position for better preservation of cork recovery after extraction.

- The product must not be stored in a location exposed to sunlight, heated environment and in direct contact with the ground

All Amorim Cork, S.A. products comply with existing regulations and legislation (European and FDA - Food and Drug Administration) for products in contact with food.