- Portfolio

- Product

Portfolio

BackSpark® Top III NDtech

The high-performance stopper for exceptional sparkling wines

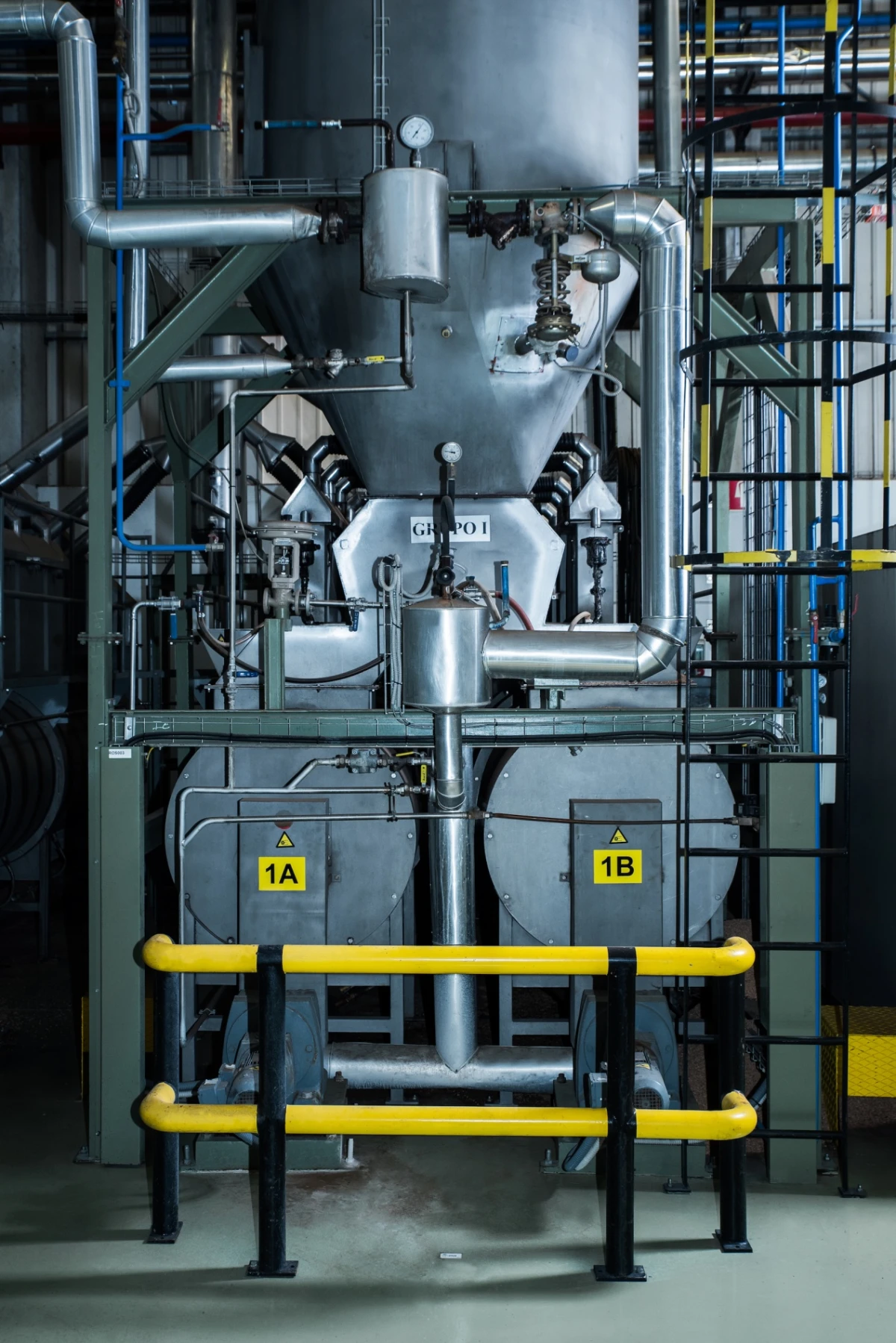

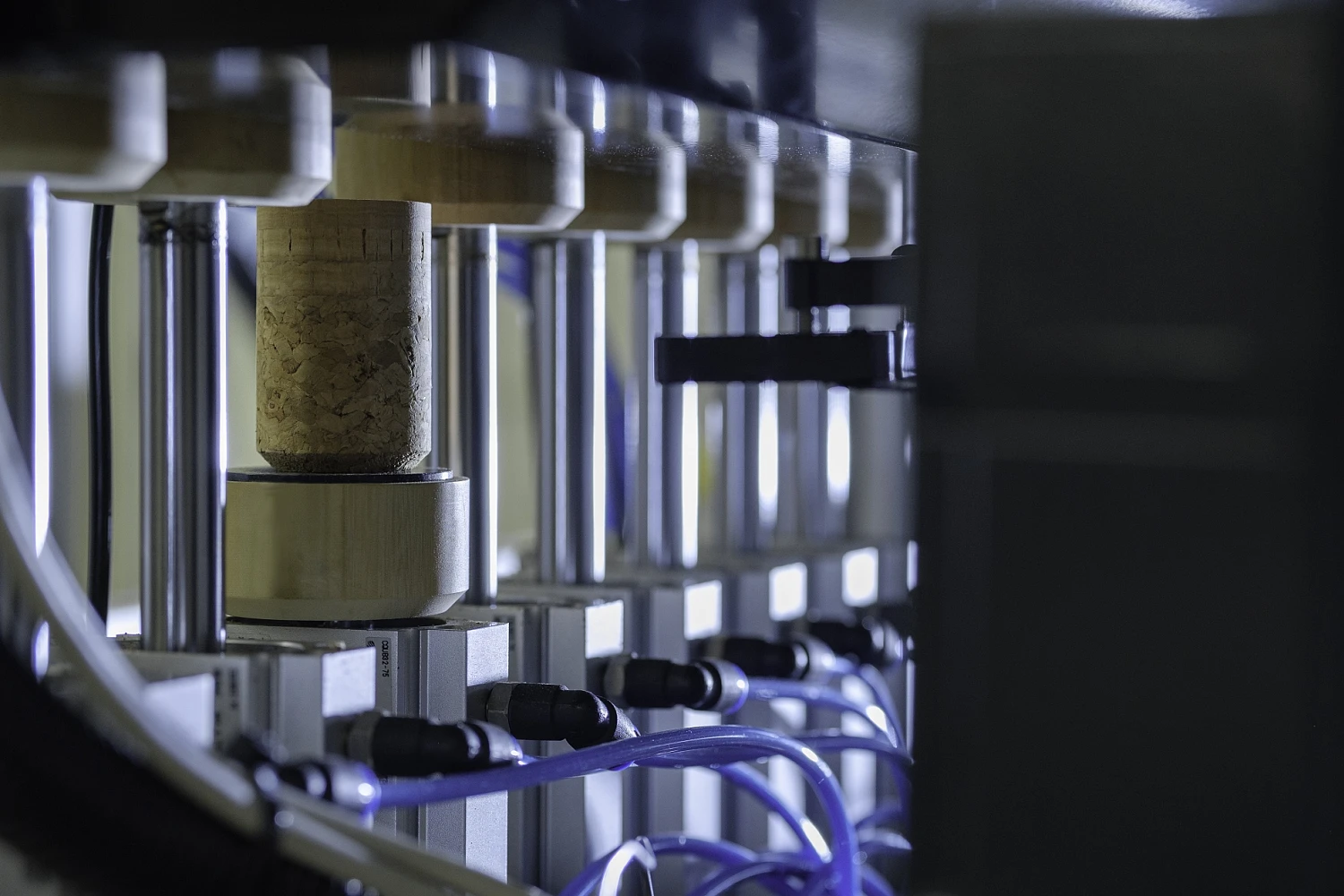

NDtech® is the industry's most advanced screening technology

The cork discs used are made from the finest raw materials and offer the best visual quality.

It also benefits from individual quality control through innovative NDtech® technology, which uses an ultra-fast gas chromatography process to ensure undetectable TCA levels for maximum sensory neutrality.

This process is complemented by the ROSA and FBT processes in the treatment of the granulate and CorkNova in the discs, offering sensory safety and meeting the highest quality standards.

The image conveyed by Spark® Top III NDtech, together with its technical performance, is striking and distinctive from other corks, thus raising aesthetics to a level of excellence in packaging.

Cork Properties

- 48 x 31 mm

- Amorim can calculate the required cork diameter by studying the internal profile of the bottleneck, the characteristics of the wine and the corking conditions.

- Order your cork stoppers for immediate or short-term use. Ideally, these cork stoppers should be used within four months of the date of manufacture if the storage conditions are respected.

- Store the cork stoppers in their original packages, in a well-ventilated room with controlled temperature between 15°C and 25°C and 50% to 70% humidity.

- Do not leave boxes and/or bags open with surplus cork stoppers.

- Ensure any dust its removed before corking.

- Ensure the cork is compressed smoothly, to a diameter 1.5 to 2 mm smaller than the diameter of the bore of the bottle.

- Ensure insertion of the cork is as quick as possible.

- For standard bottlenecks, the cork should be inserted at 24 mm ± 2 mm from the top of the neck with the wire wood applied.

- Minimise moisture on the inside of the bottleneck.

- Don’t leave the cork stoppers in the feeder as to avoid dust.

- Always use stoppers with a surface treatment suitable for the type of beverage, bottling process and selected bottle.

- Ensure that all dust is removed using suitable placed aspiration – particularly before inserting the cork stopper.

- Maintain the corker jaws free of nicks and signs of wear.

- Ensure proper alignment of plunger and location ring.

- Ensure corking machine operates smoothly, especially during compression.

- Clean all cork-handling surfaces regularly with chlorine-free products.

- Ensure the equipment is suited to the cork and bottle used.

- After bottling, the bottles should be kept in an upright position.

- Ideal bottle storage conditions are 12–18°C at 50–70% humidity.

- Keep the wine cellar free of insects.

- Bottles should be stored and transported in an upright position for better preservation of cork recovery after extraction.

- The product must not be stored in a location exposed to sunlight, heated environment and in direct contact with the ground

All Amorim Cork, S.A. products comply with existing regulations and legislation (European and FDA - Food and Drug Administration) for products in contact with food.