- Portfolio

- Product

Portfolio

BackNeutrocork®

The most competitive of the micro stoppers

*Carbon Footprint of natural cork stoppers, excluding NDtech® process, for standard product. For more information, please access our Carbon Footprint certificates.

*Carbon Footprint of natural cork stoppers, excluding NDtech® process, for standard product. For more information, please access our Carbon Footprint certificates.

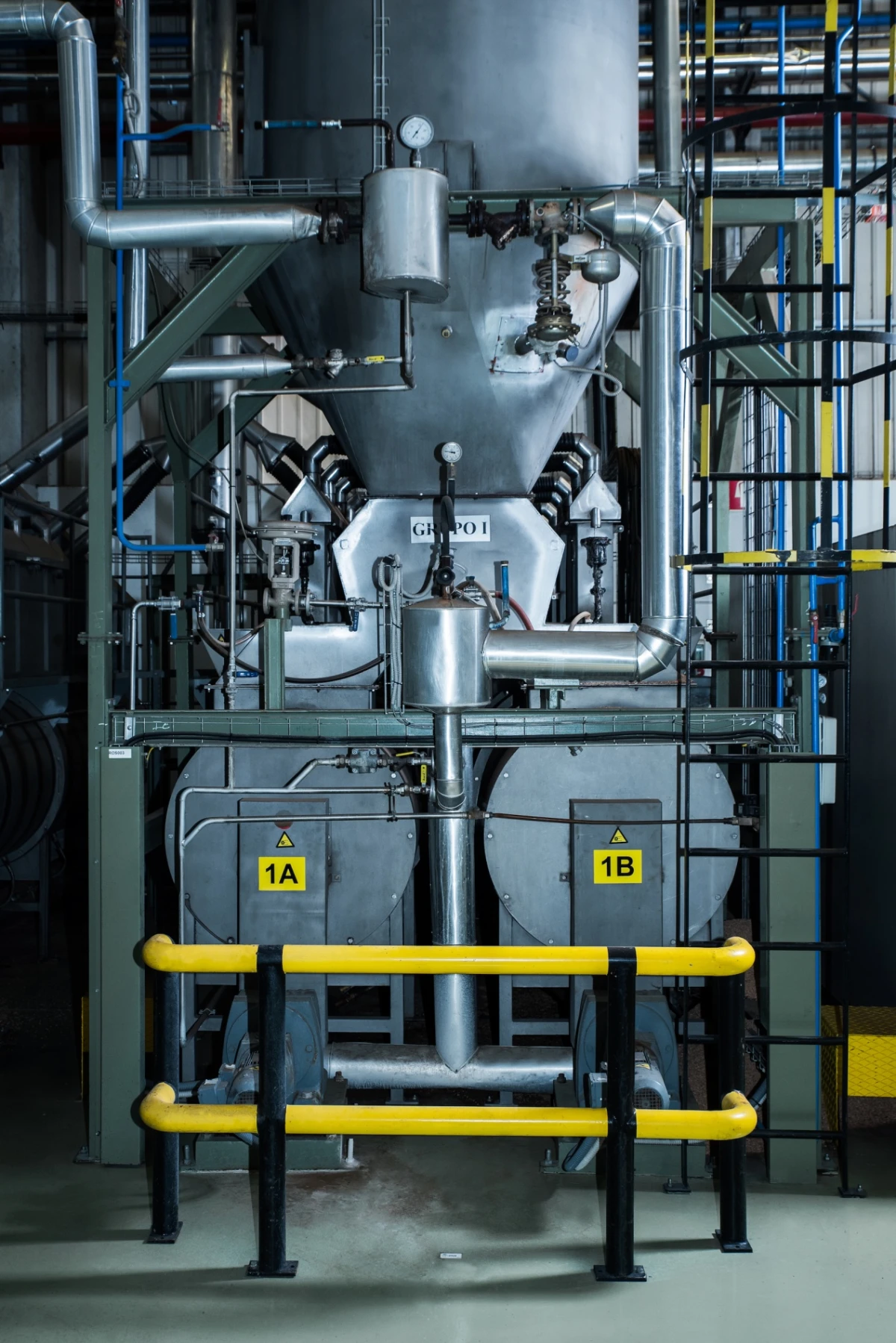

A uniform-sized micro cork granule composition

Functional, accessible and sustainable, Neutrocork® has great structural stability, resulting from a composition of uniformly sized cork micro-granules compacted in individual moulds.

Its attractive appearance and performance level make Neutrocork® an extremely competitive natural closure, designed for wines for early consumption, with an ageing potential of up to 36 months. It is also characterised by its easy extraction and is particularly suitable for high-speed bottling lines. These cork stoppers are also treated with the ROSA system, a steam-based process that removes volatile compounds, including TCA, to ensure a neutral sensory profile.

With its balance of technical reliability, visual appeal, and environmental responsibility, Neutrocork® is a smart choice for winemakers seeking a sustainable and cost-effective cork solution for wines intended for early consumption.

Cork Properties

| Tests | Characteristics | Specifications |

|---|---|---|

| Physical-Mechanical | Length | l ± 1.0 mm |

| Diameter | d ± 0.4 mm | |

| Ovalisation | ≤ 0.3 mm | |

| Moisture | 4% - 9% | |

| Specific weight | 240 - 320 kg/m3 | |

| Extraction force | 15 - 40 daN | |

| Chemical | Peroxide content | ≤ 0.1 mg/stopper |

| Dust content | ≤ 2 mg/stopper | |

| SPME GC / MS / ECD | 2, 4, 6 – Trichloroanisol (TCA) | ≤ QL (*) |

| OTR (Oxygen Transfer Rate) | 12 months | 1.20 mg/stopper |

| 24 months | 1.30 mg/stopper | |

| CO2 Footprint | -43.20 g/stopper |

* Releasable TCA content at or below the 0.5 ng/L quantification limit; analysis performed in accordance toan internal method based on ISO 20752

- 49 x 24 mm

- 44 x 24 mm / 25 mm

- 38 x 24 mm / 25 mm

- Amorim can calculate the required cork diameter by studying the internal profile of the bottleneck, the characteristics of the wine and the corking conditions.

- Order your cork stoppers for immediate use. These cork stoppers should be used within six months of the date of manufacture if the storage conditions are respected.

- Store the cork stoppers in their original packages, in a well-ventilated room with controlled temperature between 15oC and 25oC and 50% to 70% humidity.

- Do not leave boxes and/or bags open with surplus cork stoppers.

- Ensure any dust its removed before corking.

- Ensure the cork is compressed smoothly, to a diameter no less than 15,5 mm.

- Ensure insertion of the cork is a quick as possible.

- For standard bottlenecks, the cork should be inserted to 1 mm below the top of the neck.

- Minimise moisture on the inside of the bottleneck.

- Headspace should be at least 15 mm at 20oC.

- Don’t leave the cork stoppers in the feeder as to avoid dust.

- Always use stoppers with a surface treatment suitable for the type of beverage, bottling process and selected bottle.

- A vacuum must be created in order to prevent internal pressures.

- Maintain the corker jaws free of nicks and signs of wear.

- Ensure proper alignment of plunger and location ring.

- Ensure corking machine operates smoothly, especially during compression.

- Clean all cork-handling surfaces regularly with chlorine-free products.

- Ensure the equipment is suited to the cork and bottle used.

- After bottling., the bottles should be kept in an upright position for at least 10 minutes.

- Ideal bottle storage conditions are 12o-18oC at 50-70% humidity.

- Keep the wine cellar free of insects.

- Bottles should be transported in an upright position.

- The product must not be stored in a location exposed to sunlight, heated environment and in direct contact with the ground.

All Amorim Cork, S.A. products comply with existing regulations and legislation (European and FDA - Food and Drug Administration) for products in contact with food.