- Portfolio

- Product

Portfolio

BackAcquamark®

Safety and prestige at a competitive cost

*Carbon Footprint of natural cork stoppers, excluding NDtech® process, for standard product. For more information, please access our Carbon Footprint certificates.

*Carbon Footprint of natural cork stoppers, excluding NDtech® process, for standard product. For more information, please access our Carbon Footprint certificates.

Based on a water-based solution

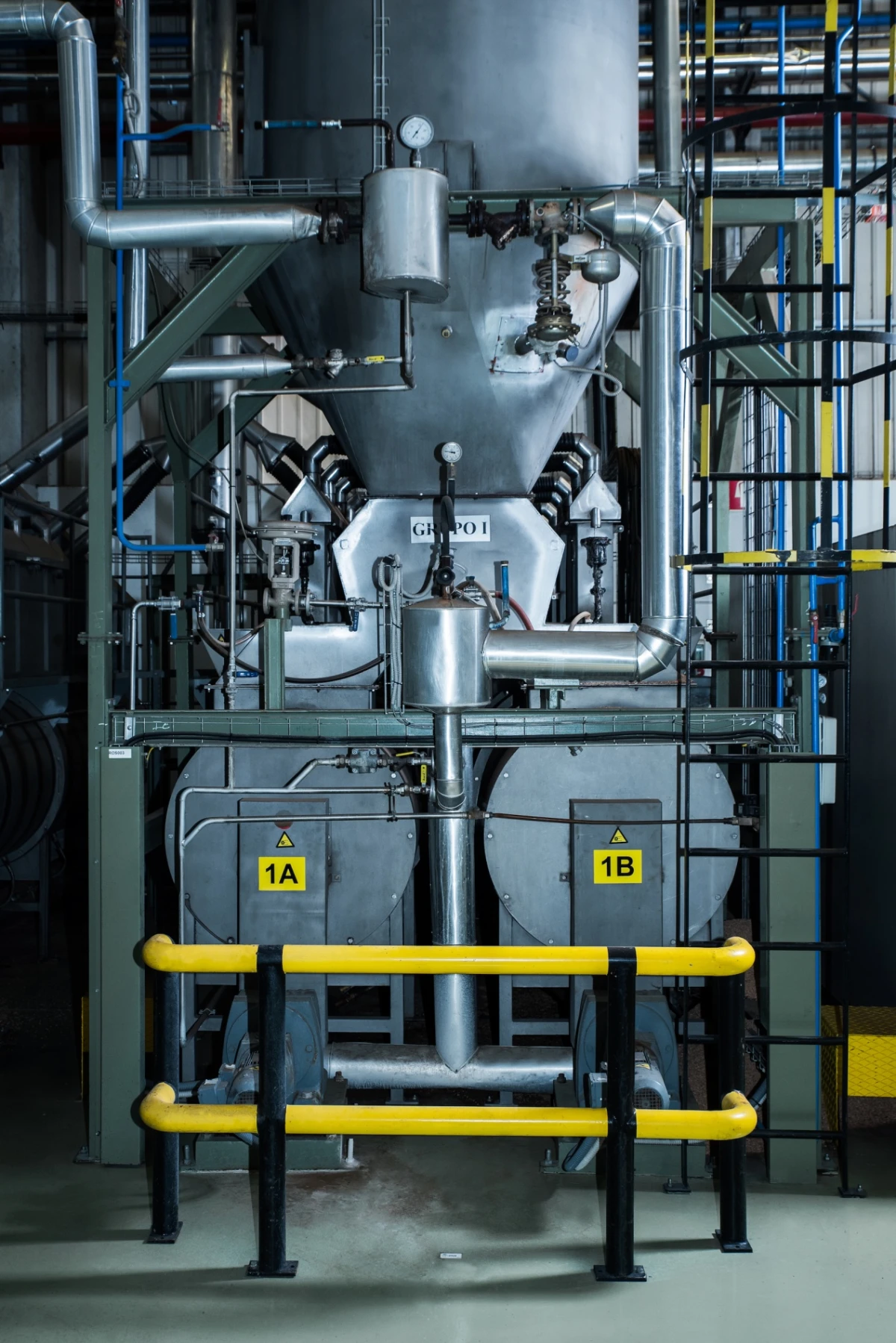

Acquamark® 's coating is produced through a high-tech structural process, based on a water-based solution which binds the cork extracts to the stopper's surfaces. This coating enhances the product's sealing potential and result in a smoother, more uniform appearance.

Each Acquamark®stopper undergoes rigorous quality control, including the Sealing Verification System (SVE), which validates the tightness of every individual cork. The entire production process is fully traceable, ensuring consistent quality and compliance

with the highest industry standards.

Combining natural aesthetics with cutting-edge technology, Acquamark® offers winemakers a reliable, sustainable, and visually appealing closure solution.

Cork Properties

| Tests | Characteristics | Specifications |

|---|---|---|

| Physical-Mechanical | Length (l) | l ± 1.0 mm |

| Diameter (d) | d ± 0,5 mm | |

| Ovalisation | ≤ 0,7 mm | |

| Moisture | 4% - 8% | |

| Extraction force | 20 - 40 daN | |

| Chemical | Peroxide content | ≤ 0.1 mg/stopper |

| Dust content | ≤ 3mg/stopper | |

| Visual | Visual Grade (1) | ≥ 5% |

| CO2 Footprint | - 41.69 g/stopper |

- 38 x 24 mm

- 45 x 24 mm

- 49 x 24 mm

- Amorim can calculate the required cork diameter from the design of the neck of your bottle, the characteristics of the wine and the corking conditions.

- For wines which are to age in the bottle, we suggest the use of corks longer than what is normal.

- Order your stoppers for immediate or short term use. These stoppers should be used within 6 months of the date of manufacture.

- Store in a well-ventilated room with controlled temperature between 15°C and 25°C and 50% to 70% humidity.

- Ensure any dust is removed before corking.

- Ensure the cork is compressed slowly to a diameter of not less than 15.5mm.

- Ensure insertion of the stopper is performed as quickly as possible.

- For standard bottlenecks, the cork should be inserted to 1mm below the top of the neck.

- Minimise moisture on the inside of the bottle neck.

- Headspace should be at least 15 mm at 20ºC.

- Don't leave the cork stoppers in the feeder as to avoid dust.

- Always use stoppers with a surface treatment suitable for the type of beverage, bottling process and selected bottle.

- A vacuum must be created in order to prevent internal pressures.

- Always ensure the corker jaws are free of nicks and signs of wear.

- Ensure proper alignment of plunger and location ring.

- Ensure corking machine operates smoothly, especially during compression.

- Regularly clean all surfaces that come into contact with cork with chlorine-free products.

- Ensure the equipment is suited to the cork used.

- After bottling, the bottles should be kept in an upright position for at least 10 minutes.

- Ideal bottle storage conditions are: 15-20°C at 50-70% humidity.

- Keep the wine cellar free of insects.

- Bottles should be transported in an upright position.

- The product must be stored in a location exposed to sunlight, heated environment and in direct contact with the ground.

All Amorim Cork, S.A.'s products comply with current regulations and legislation (European and FDA - Food and Drug Administration) for products in contact with food.