- Portfolio

- Product

Portfolio

Back

Helix

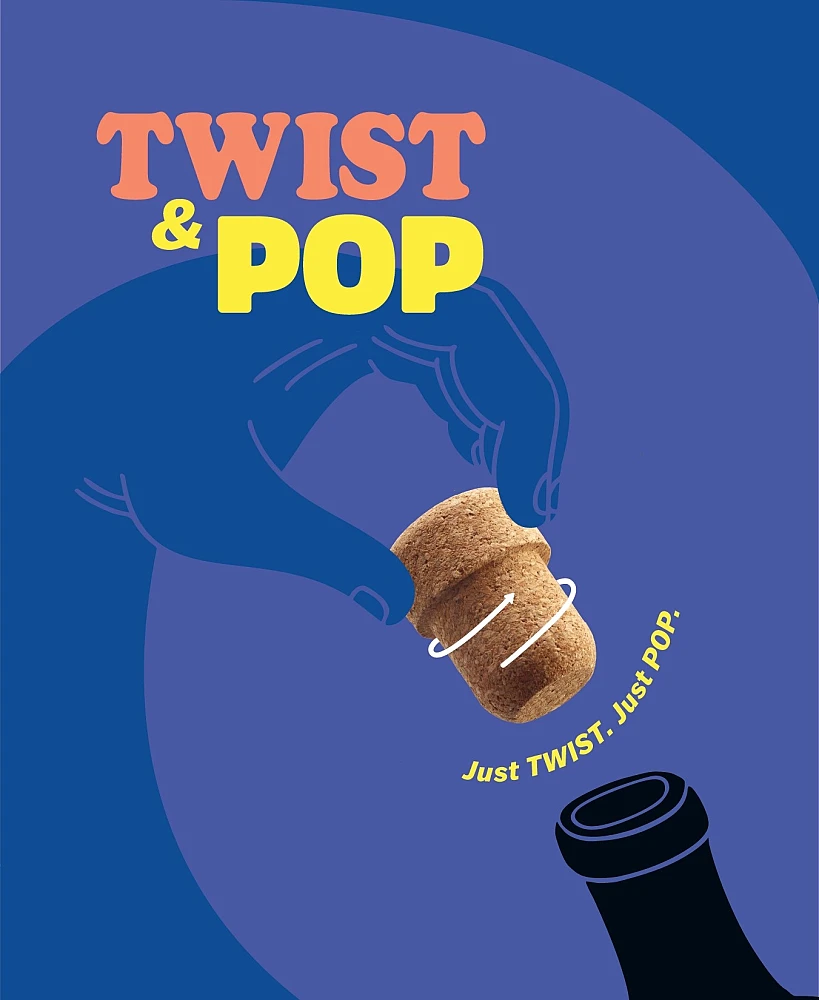

The unexpected twist for still wines

Twist & Pop

Helix is a game-changer in wine closures, combining cork’s performance and sustainability with the convenience of a modern resealable system.

A micro-granulated stopper that doesn’t require a corkscrew, designed for original wines, enabling fractioned consumption without compromising wine quality.

This stopper retains all the traditional benefits of cork: optimal oxygen ingress, airtight sealing, and advanced anti-TCA protection, ensuring the wine stays fresh, aromatic, and high-quality, even when enjoyed over multiple occasions.

Helix fits standard CETIE bottle neck profiles and requires no major changes to bottling lines, providing flexibility for producers. Its premium look and customizable branding options enhance the perceived value of wine, helping products stand out in a competitive market.

Ideal for consumers seeking innovation, sustainability, and authenticity, Helix is perfect for organic, no/low-alcohol, and premium wines. It’s the smart choice for brands aiming to revolutionize the wine experience.

Cork Properties

| Tests | Characteristics | Specifications |

|---|---|---|

| Physical-Mechanical | Dimensions |

37 x 29 x Ø 24 / 23 mm |

| Specific weight | 240 - 320 kg/m3 | |

| Raw material | ROSA-treated granulated cork 0.5 - 2 mm | |

| Production production | Individual Moulding | |

| Moisture | 2% - 8% | |

| Physical-Chemical | Peroxide content | ≤ 0.1 mg/cork |

| Dust content | ≤ 2 mg/cork | |

| TCA | ≤ 0.5 mg/cork | |

| OTR | 12 months | 1.20 mg O2 |

| After 1st year | 0.08 mg O2 |

Compatible with all standard bottles featuring a CETIE neck profile.

- Bordeaux

- Burgundy

- Champagne

- Rhine

- Amphora

- Albeisa

- Amorim can calculate the required cork diameter by studying the internal profile of the bottleneck, the characteristics of the wine and the corking conditions.

- Order your cork stoppers for immediate use. These cork stoppers should be used within six months of the date of manufacture if the storage conditions are respected.

- Store the cork stoppers in their original packages, in a well-ventilated room with controlled temperature between 15°C and 25°C and 50% to 70% humidity.

- Do not leave boxes and/or bags open with surplus cork stoppers.

- Maximum diameter of the rinsing tube is 14 mm.

- Ensure the neck gripping system is aligned with the rinsing head.

- Maximum diameter of the filling tube is 16 mm, recommendation is 14 mm.

- Ensure the neck of the bottle is centered with the cone before inserting the filling tube.

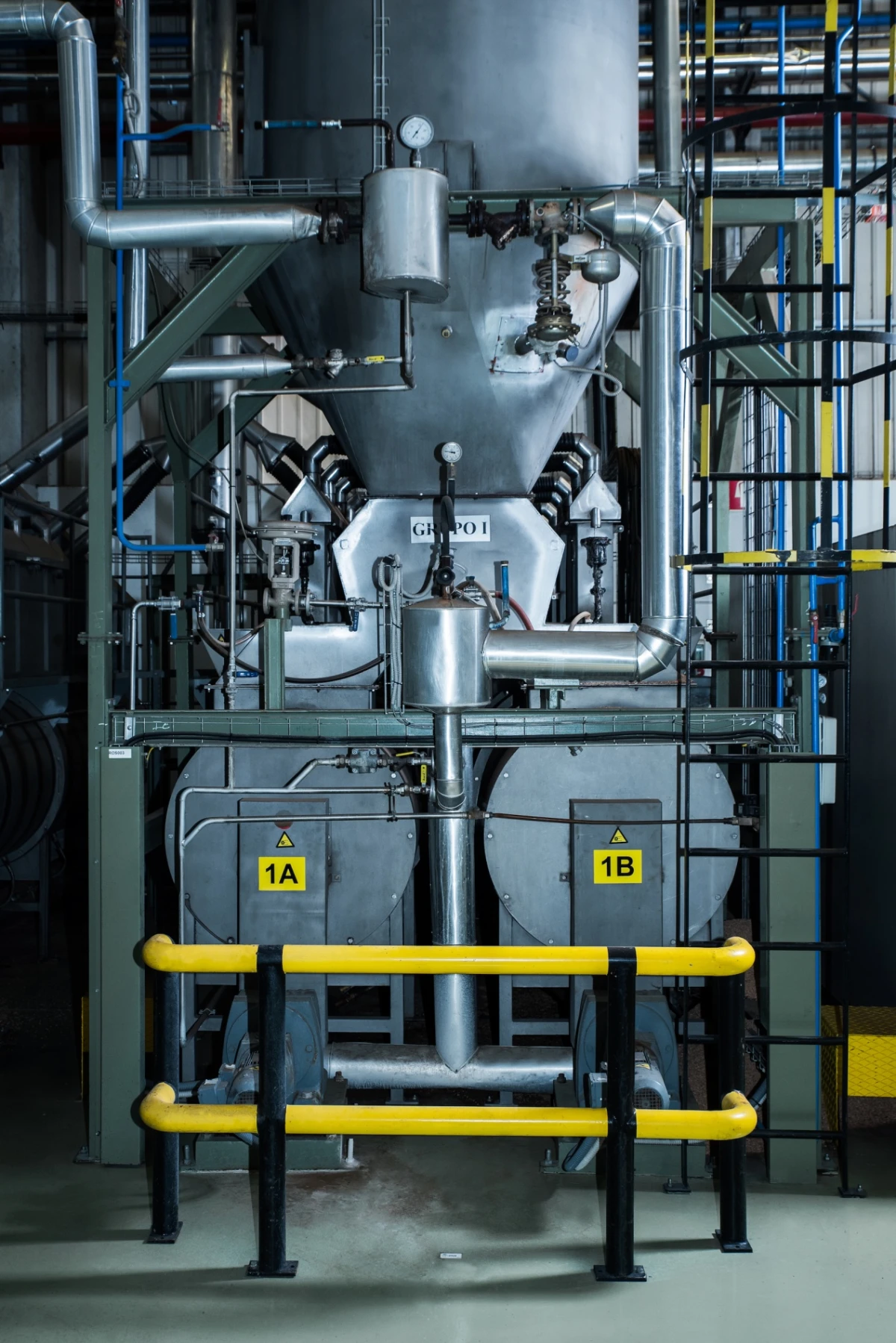

- Helix can be used on all standard bottling machines with a vacuum system.

- It must be employed in corking lines with orientation equipment.

- Ensure any dust is removed before corking.

- Ensure the cork is compressed smoothly, to a diameter no less than 15.5 mm.

- Ensure insertion of the cork is as quick as possible.

- Since Helix is a partial insertion cork, a specific adjustment of the corking machine is required. The insertion of the cork should stop 1 mm above the edge of the neck.

- Minimise moisture on the inside of the bottleneck.

- Headspace should be at least 15 mm at 20°C.

- Always use stoppers with a surface treatment suitable for the type of beverage, bottling process and selected bottle.

- A vacuum must be created in order to prevent internal pressures.

- Ensure that all dust is removed using suitable placed aspiration – particularly before inserting the cork stopper.

- Maintain the corker jaws free of nicks and signs of wear.

- Ensure proper alignment of plunger and location ring.

- Ensure corking machine operates smoothly, especially during compression.

- Clean all cork-handling surfaces regularly with chlorine-free products.

- Ensure the equipment is suited to the cork and bottle used.

-

After bottling, the bottles should be kept in an upright position between 5 and 10 minutes.

- Ideal bottle storage conditions are 15°-25°C at 50-70% humidity.

- Keep the wine cellar free of insects.

- Bottles should be transported in an upright position.

- The product must not be stored in a location exposed to sunlight, heated environment and in direct contact with the ground.